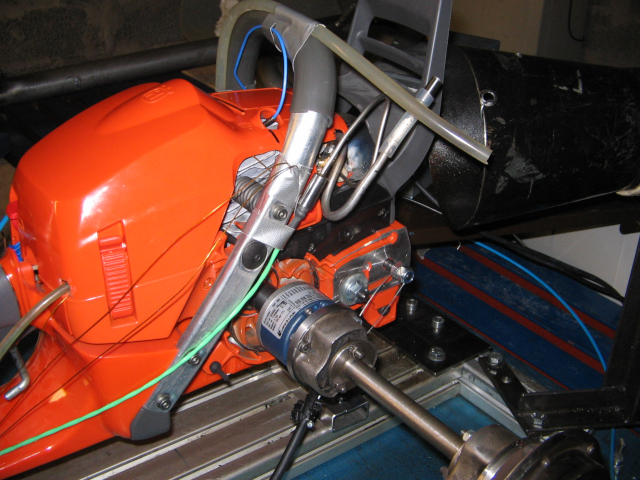

Crank angle degree measurement

Pressure measurement

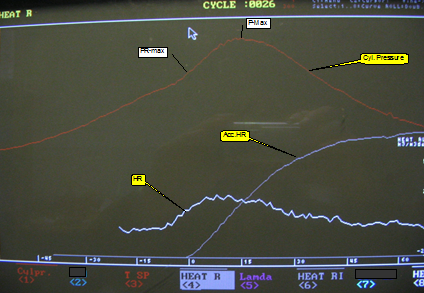

Measuring, calculating, evaluating and optimising the combustion

We frequently use pressure transducers when to measure and evaluate the combustion. These are the most valuable tools when to understand the impact of a modification.

The crank angle degree is measured by using incremental equipment.

Through the years we have made great effort to improve the TDC position determination in the CAD equipment, which is of utmost importance when calculating the IMEP values.

Examples of values are peak pressure and position, peak pressure rise and position and heat releases. Each parameter is documented for each cycle during the chosen load-point. For steady state conditions, 300 cycles are normally documented.

Combustion analysis is of great interest also during transient conditions. It can be a very helpful tool when optimising different parameters from idle to full throttle.

We have successfully developed the use of incremental CAD units to small water-dynos mounted directly on the crank shaft. This makes it possible to study the combustion during test-cycles and simulating different operational situations.

We use in-house instruments for combustion knock evaluations, which filter the combustion signal, leave the knocking fluctuations to a straight line and count the cycles that reach different levels of knocking. Which can be very helpful when sorting out what type of knocking, and how much, that should be allowed.